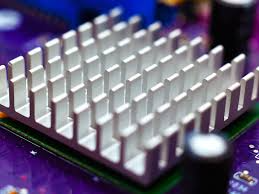

Managing heat well is key to making electronic devices work better and last longer. Whether you’re building a gaming PC, a smartphone, or a car system, choosing the right heat sink material matters. There are many options, like regular aluminum or special copper alloys.

So, how do you choose the best one? In this blog post, we’ll explain how heat travels through materials and which ones do the best job of cooling. You’ll see how picking the right material can help your project run smoothly and stay cool!

What Makes a Material Ideal for Heat Sinks?

An ideal heat sink material helps quickly move heat away from electronic parts to keep them cool and working well. The key qualities to look for are:

- High Thermal Conductivity

The material should be great at conducting heat, this lets heat travel fast from the component to the heat sink fins where it cools down. Copper and aluminum are good examples.

- Lightweight

Especially important for portable devices like laptops or airplanes, lightweight materials keep the overall device light without hurting cooling ability.

- Cost-Effective

The material should balance good performance with reasonable cost. Copper cools better but is expensive, while aluminum is cheaper and works well for many uses.

- Corrosion Resistance

Materials that resist rust and corrosion, such as anodized aluminum, help heat sinks last longer and maintain effective cooling in different environments.

- Mechanical Strength and Durability

The material must resist pressure, vibrations, and temperature changes without breaking. Aluminum is easier to shape but less strong, while copper is stronger but less flexible.

- Ease of Manufacturing

Materials that are easy to shape, extrude, or machine makes it possible to create complex heat sink designs with thin fins and large surfaces, which help improve cooling.

- Compatibility with Surface Treatments

The material should work well with coatings (like anodizing or plating) that improve corrosion resistance and heat radiation.

Top Heat Sink Materials

A. Aluminum

Aluminum is a light metal that moves heat well and is easy to shape, so it’s commonly used to cool everyday electronics. It costs less than copper and doesn’t rust because it has a natural protective coating. But it’s not as strong or long-lasting as copper.

Pros:

- Lightweight and affordable.

- Resists corrosion naturally.

- Easy to shape and manufacture.

Cons:

- Doesn’t conduct heat as well as copper.

Best For: Consumer electronics, LED lighting, general uses.

B. Copper

Copper is a metal that moves heat very well, so it’s great for cooling powerful electronic parts. But it’s heavier and costs more than aluminum. Copper is also less bendable but stronger and lasts longer.

Pros:

- The most common material that conducts heat best.

- Very good at cooling by moving heat away fast.

Cons:

- It’s heavier to carry and costs more money.

- It can slowly form a dull or rusty coating on its surface as time passes.

Best For: High-performance CPUs, GPUs, industrial electronics.

C. Copper-Aluminum Hybrid

A heat sink design that uses a copper base to absorb heat quickly and aluminum fins to spread and release that heat efficiently.

Pros:

- Good balance of performance and lighter weight.

Best For: PC cooling, mid-to-high-performance electronics.

D. Graphite and Pyrolytic Graphite Sheet (PGS)

These are advanced materials known for excellent heat conduction. Graphite is lightweight and flexible, while Pyrolytic Graphite Sheet (PGS) offers even better thermal performance and is often used in high-tech cooling applications.

Pros:

- Very lightweight.

- Excellent heat conduction in one direction.

Cons:

- It’s easy to break and costs a lot.

Best For: Smartphones, tablets, compact devices.

E. Ceramics

Ceramics are materials that aren’t metal but can move heat well without conducting electricity. They’re light, can handle heat and wear, but can break easily. People use ceramics when they need good cooling and to keep electricity from passing through.

Pros:

- Allows heat to pass through easily but does not conduct electricity.

Cons:

- Easily breaks or cracks because it’s not very flexible.

- Some materials, such as BeO (beryllium oxide), can be dangerous if you breathe in their dust or tiny particles.

Best For: Power electronics, radio frequency (RF) modules

F. Metal Matrix Composites (MMC)

Metal Matrix Composites (MMCs) are made by mixing metals with other materials like ceramics to make them stronger, better at handling heat, and last longer. They work better than regular metals for cooling and handling stress but usually cost more and are harder to make.

Pros:

- It can be customized to provide the exact level of heat transfer and strength required.

Cons:

- Costly and requires special equipment or skills.

Best For: Aerospace, military, advanced computing.

This comparison helps you choose the right heat sink material by matching strengths and weaknesses to your application needs.

Comparing Aluminum vs. Copper: Which is Best?

1. Thermal Conductivity

- Copper: About 398 W/m·K, excellent at moving heat quickly, perfect for high-performance uses.

- Aluminum: About 205 W/m·K, not as good as copper but still works well for most standard needs, especially if designed properly.

2. Weight

- Copper: Heavy (density ~8.96 g/cm³), which can be a problem in devices where keeping weight low is important (like laptops or aerospace).

- Aluminum: Light (density ~2.7 g/cm³), great for applications where reducing weight matters.

3. Cost

- Copper: Copper is much more expensive, so it’s not ideal for budget-friendly projects.

- Aluminum: Cheaper and widely available, making it the popular choice for many products.

4. Corrosion Resistance

- Copper: Resists corrosion but can tarnish over time, especially in humid places.

- Aluminum: Aluminum naturally forms a thin coating that protects it from rust, so it works well in many different environments.

5. Manufacturability

- Copper: Harder to machine and shape, which can increase production time and costs.

- Aluminum: Easier to work with, allowing for complex shapes and faster manufacturing.

When to Use Which:

- Copper: Choose copper for top-tier heat dissipation, especially in high-performance CPUs, GPUs, or industrial electronics.

- Aluminum: Choose aluminum if you want a lightweight, affordable option that’s easier to manufacture, great for consumer electronics, LED lighting, and everyday uses.

Surface Treatments That Enhance Material Performance

1. Anodizing (for Aluminum)

Anodizing is a treatment that makes the natural protective layer on aluminum thicker and stronger.

Benefits:

- Better corrosion resistance: Protects aluminum from damage by air and moisture, making it last longer.

- Improved heat radiation: Helps the heat sink release heat more efficiently, which is great for cooling without fans.

- Color options: The anodized layer can be dyed, so the aluminum can come in different colors for design purposes.

Where used:

Common in consumer electronics, LED lights, and general products needing durable and efficient cooling.

2. Nickel Plating (for Copper)

Nickel plating means covering the copper surface with a very thin layer of nickel to protect it from corrosion and wear.

Benefits:

- Prevents oxidation: Keeps copper from tarnishing, so it keeps conducting heat well over time.

- Increases durability: Makes the copper surface harder and more resistant to wear and damage.

- Improves corrosion resistance: Protects against harsh environmental conditions, extending lifespan.

Where used:

Ideal for high-performance electronics like CPUs, GPUs, and industrial equipment that need both strong heat dissipation and toughness.

3. Black Coating

Applying a black finish like black anodizing or black oxide on heat sinks.

Benefits:

- Better heat radiation: Black surfaces emit heat more effectively, improving passive cooling.

- Looks sleek: Gives a clean, professional black finish for good aesthetics.

Where used:

This material is commonly used in cooling setups without fans, such as LED lights, audio devices, and regular electronics.

Using the right surface coating helps heat sinks last longer, cool more efficiently, and look better, so they work best for their purpose.